Committed to a sustainable future

GMA Garnet™ is committed to developing a sustainable future for our business, customers, employees, and the communities and environment we live and work in.

Committed to a sustainable future

GMA Garnet™ is committed to developing a sustainable future for our business, customers, employees, and the communities and environment we live and work in.

Sustainability from mine to customer

GMA has a proud history of sustainable mining practices and is taking active steps to limit our environmental impact.

GMA is committed to reducing landfill and creating a longer lifespan for every grain of garnet mined while creating more value for our customers. We invest heavily in developing new technologies and processes to further reduce environmental impacts, from mine to the customer, and continue to focus on innovation in garnet reprocessing.

What is garnet reprocessing?

Garnet reprocessing provides customers with a cost-effective and responsible option for managing used garnet. It restores used garnet to a "same as virgin" state — a breakthrough from over 20 years of research and development and a seismic shift in garnet waste management.

Tens of thousands of tons have been saved from going into landfills over the last 20 years, and we look forward to seeing those numbers grow.

GMA 2024 Sustainability Report

Our 2024 Sustainability Report marks the second year of formal reporting for GMA — and a clear shift from establishing our ESG foundations to embedding them into the way we work, plan, and grow.

Developing safer abrasives

GMA takes health and safety seriously. We produce the safest abrasives with minimal risks to the people who use them and the surrounding communities and environment.

Garnet is a naturally occurring, chemically inert mineral with near-zero worker safety and environmental contamination risks. Our products are tested every two hours and accredited by third parties that verify product safety against global and regional industry standards. As a result, GMA Garnet™ has very low dust and virtually no heavy metals, silica, or other harmful substances.

-1.jpg?width=470&height=500&name=mask%20(1)-1.jpg)

GMA Sustainability Awards Program

The GMA Sustainability Awards recognize outstanding contributions to sustainability across the abrasive blasting and waterjet cutting industries. Open to GMA customers and partners, the awards highlight those demonstrating leadership through responsible garnet return and recycling practices.

Our commitments to sustainable mining

Land rehabilitation

GMA rehabilitates its mined areas to their original state or often an improved condition. Seeds are collected from the surrounding environment and then propagated, planted, and nurtured, ensuring the ecosystem returns to its natural state. This practice minimizes our environmental impact long-term and supports biodiversity.

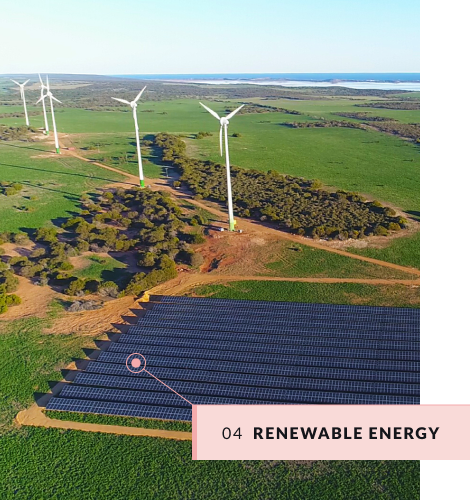

Renewable energy sources

GMA has committed to supply 70% of the energy required for our West Australian mine and processing plant from a three-megawatt wind and solar farm — an initiative that will reduce our carbon footprint by approximately 5,000 metric tons of carbon dioxide per annum.

Emissions offsetting

GMA has committed to offsetting our remaining greenhouse gas emissions by investing in several climate protection projects around the world. This is implemented via our partner, South Pole, and contributes toward the United Nations’ Sustainable Development Goals.

GMA TougBlast™ 20/100

GMA TougBlast™ 20/100 GMA Garnet™ 30/60

GMA Garnet™ 30/60 GMA Garnet™ 80 Mesh

GMA Garnet™ 80 Mesh Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Waterjet Parts

Waterjet Parts Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile