Confidence in every cut

Engineered to perform. Trusted for reliability. Supported by experts. For over 40 years, GMA Garnet™ has been backed by industries worldwide for precision cutting, consistent supply and high quality performance.

Confidence in every cut

Engineered to perform. Trusted for reliability. Supported by experts. For over 40 years, GMA Garnet™ has been backed by industries worldwide for precision cutting, consistent supply and high quality performance.

The world’s most popular waterjet garnet

GMA waterjet abrasives are engineered for peak performance, accuracy, and speed. Refined over 40 years alongside industry experts, our products are the first choice of operators who demand ultra-precise waterjet cutting.

GMA’s world-class processing facilities guarantee every batch contains consistent-sized grains of the purest garnet, ensuring steady abrasive flow, reduced consumption, and less downtime for maintenance and parts replacement.

The GMA advantage

Engineered for precision cutting

GMA’s range of waterjet cutting abrasives strikes the perfect balance of cutting efficiency and edge quality for results that improve production uptime.

Hardness

The harder the grain the better it cuts. Our garnet is hard, tough, and dense — the perfect combination for fast and effective cutting, with low abrasive consumption and excellent edge quality.

Consistent grain sizing

Inconsistent grain sizing causes blockages, creating unsteady abrasive pressure and flow, fluctuating cutting speed, and poor edge quality.

Our processing methods ensure every bag contains the most precisely-sized grains of garnet. It accelerates production and reduces the frequency of expensive parts replacements.

Cleanliness & purity

Dusty, dirty, or impure garnet impacts cutting performance, causes frequently blocked focussing tubes, or even damaging the parts being cut. However, GMA’s advanced processing methods produce the cleanest garnet for the cleanest results.

Why is GMA Garnet™ the preferred waterjet abrasive?

Achieve the highest production rates and a perfect result on the first cut.

Proven performance

Engineered for precision, speed and uptime so you can cut cleaner, faster and more efficiently.

Sustainable resource

Responsibly mined and resource-efficient, GMA Garnet™ supports our customers for long-term sustainability, from mine to machine.

Pure precision

Precisely graded, High-purity garnet engineered for optimal flow, cleaner cuts and consistent performance across every job.

Secure supply

From mine to customer, we manage the process, ensuring uninterrupted access to the world’s most trusted waterjet garnet.

Trusted expertise

Our team doesn’t just supply garnet; they’ve cut with it. Technical support from experienced specialists who understand your projects, business and goals.

Longstanding partnerships

Trusted by leading waterjet manufacturers based on decades of proven performance.

Waterjet abrasive for all applications

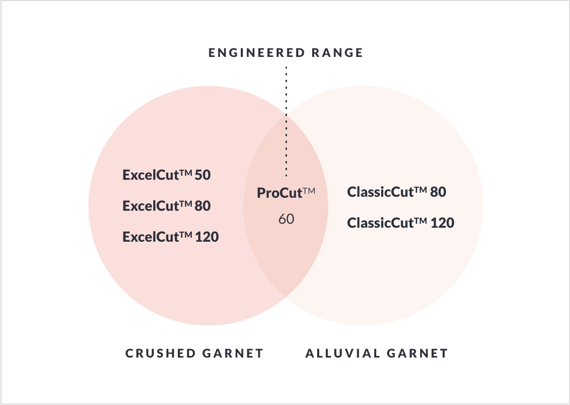

GMA offers a range of crushed and alluvial almandine garnet grades for any waterjet cutting operation.

GMA ExcelCut

The sharpest crushed hard rock garnet for cutting thick hard materials or those requiring minimal refinishing.

Mesh

50, 80, and 120 mesh

Focusing tube

0.020" - 0.060"

Orifice

0.007" - 0.018"

GMA ProCut™

An engineered blend of crushed hard rock and alluvial garnet ideal for high-volume waterjet cutting operations.

Mesh

60 mesh

Focusing tube

0.040" - 0.050"

Orifice

0.012" - 0.014"

GMA ClassicCut™

The most versatile all-purpose waterjet abrasive, recognized as the industry standard by manufacturers globally.

Mesh

80 and 120 mesh

Focusing tube

0.020" - 0.040"

Orifice

0.007" - 0.014"

Speak to your regional GMA expert now

We know the waterjet cutting business, and are here to help you get the most out of your operation. Ask us for advice, a product sample, or demo.

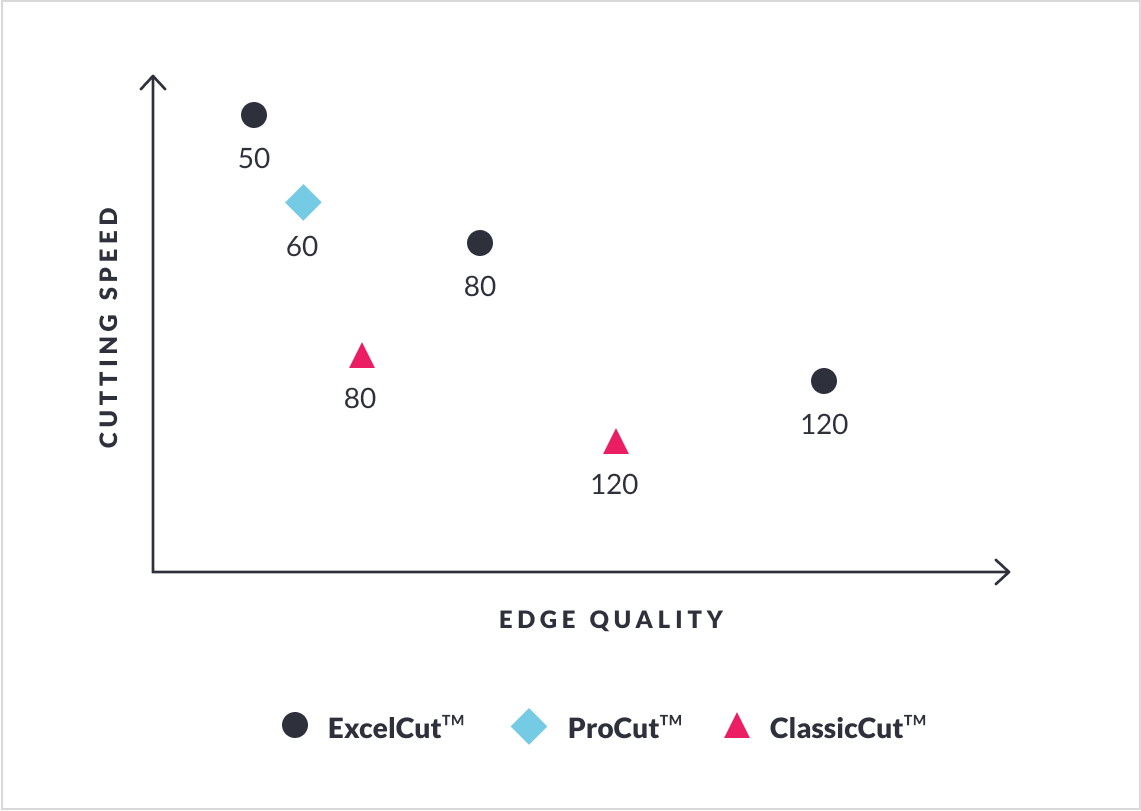

Select the right abrasive for your project

What grade of garnet is right for your project? With GMA's world class waterjet garnet abrasives, no matter what you're cutting you can be confident that you can maximize production and minimize downtime.

*This chart is a general guide only. Product performance variation may occur due to difference in material type, thickness, equipment brands and water pressure.

Waterjet abrasive resources

Ready to experience the GMA difference?

Speak to your regional expert about our waterjet products, or request a sample or demo.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile