GMA ToughBlast™ Powers Through

Engineered for high performance in demanding coating removal jobs up to 30 mil, including tank linings, shipyards, bridges, and oil & gas facilities.

3.0 - 4.0 mil

Surface profile

Up to 360 ft2/hr

Blasting rate

As low as 1.5 lb/ft2

Consumption rate

GMA ToughBlast™

GMA ToughBlast is an engineered blend garnet abrasive designed to power through heavy industrial coatings. Achieve high blast rates and your required profile on heavily rusted or pitted surfaces, tank lining maintenance, 2 or 3 coat systems, maintenance on pipes, pressure vessels, and offshore platforms.

Keep your projects on schedule and reduce your costs with the abrasive that cuts and cleans faster than traditional blast abrasives.

Industry Applications

Proven performance in surface preparation

High productivity

Cut blasting hours by 30-50%* compared to slag abrasives. GMA ToughBlast™ performance has been demonstrated through rigorous product testing and a track record of success in applications worldwide.

Cost-effective blasting

Deliver fast results at the lowest cost. GMA Garnet™ can provide significant savings in abrasive consumption, blasting hours, and disposal costs for your project. Overall, garnet sandblasting generally requires 30–50% less product than waste slag.*

Ideal surface finish

GMA ToughBlast™ achieves an exceptionally clean surface and high peak density. Our uniquely hard and tough garnet blend cuts through resilient coatings, allowing operators to prepare surfaces quickly for inspection and recoating.

Safe and compliant

Have complete peace of mind knowing GMA Garnet™ meets all industry, government safety, and environmental standards. Blasting the purest, cleanest garnet means less dust, leading to better operator visibility and less worker risk.

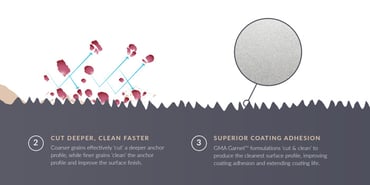

Why engineered blends perform better

GMA’s sharp, angular hard rock garnet cuts through the toughest, thickest coatings up to 30 mil and creates a consistent surface profile up to 4.0 mil. With the addition of fine, subangular alluvial garnet, ToughBlast™ removes all traces of surface embedment and contaminants. This dual-action performance ensures speed and efficiency on the toughest coating removal jobs and improves blasting production rates.

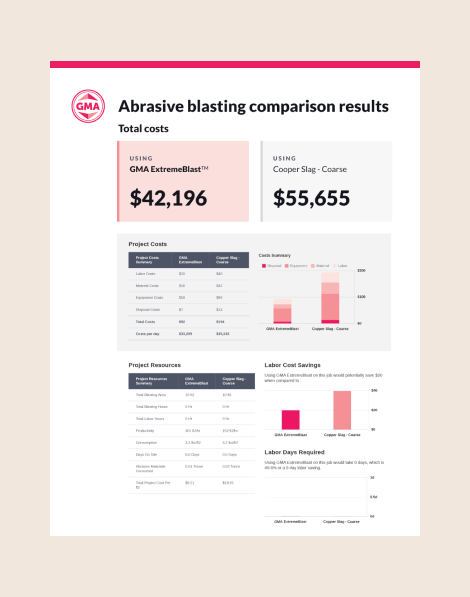

How much money can the right abrasive save you?

When estimating your abrasive blasting project costs, the abrasive price won’t tell the whole story.

Forecast your profitability with an abrasive cost comparison based on independent third-party analysis. Simply provide project costs and specs, then select a GMA abrasive and an alternative

70% abrasive consumption saved with GMA ToughBlast™

A shipyard in New York harbor recently switched from using slag abrasives to GMA ToughBlast™ garnet. Results showed an impressive increase in efficiency from each blaster, and a drastic reduction in the consumption rate and downtime required to refill the blasting pots.

Learn more about GMA ToughBlast™

Speak to an expert about GMA ToughBlast™

Request a product sample or onsite demo, or find your nearest GMA distributor.

GMA Newsletter

Subscribe to our e-newsletter for the latest news and events at GMA.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA ClassicCut™

GMA ClassicCut™ GMA ExcelCut™

GMA ExcelCut™ Ilmenite

Ilmenite Pyroxene

Pyroxene