Blast abrasives engineered to perform

GMA Garnet™ sandblasting media cuts and cleans faster to optimize performance for any surface preparation project.

Blast abrasives engineered to perform

GMA Garnet™ sandblasting media cuts and cleans faster to optimize performance for any surface preparation project.

Maximize productivity to meet project deadlines

GMA’s high-performance range of garnet blasting media is engineered to maximize productivity and significantly reduce the cost of surface preparation jobs.

Approved by paint manufacturers worldwide, GMA is the preferred choice of oil & gas companies, full-service shipyards, industrial contractors, and fabricators. From removing resistant coatings and heavy rust to delicate restoration work, GMA helps you complete projects on time and budget.

The GMA advantage

GMA Garnet™ is a strong natural mineral that outperforms other abrasives due to its inherent hardness, toughness, density, and angularity. These qualities, when combined with the recommended equipment and air pressure, provide teams with unmatched performance, such as:

- Fast removal of tough coatings

- A deep anchor pattern

- No surface embedment

- A consistent surface profile.

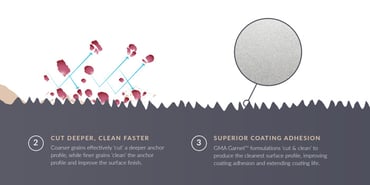

What is an engineered blend?

GMA’s range of garnet blast abrasives are exclusively engineered blends, a mix of coarse and fine garnet grains, achieving the optimal balance between cutting and cleaning power.

Engineered blends, explained

Typical sandblasting media is generally one-dimensional, containing either coarse or fine grains. GMA's range of Engineered Blend garnet abrasives are a unique mix of coarse and fine garnet grains, achieving the optimal balance between cutting power and cleaning ability.

Grain size matters

Coarse grains can cut through thick coatings and create a deep surface profile, but leave behind significant surface embedment. Used alone they cannot thoroughly clean small valleys or pits, resulting in slow cleaning rates, high abrasive consumption, and a higher risk of corrosion and coating failure.

The cause for change

Fine grains produce a cleaner surface and are more efficient at removing thin coatings like mill scale than coarse grains. However, they are ineffective for thick coating removal and cannot produce the deep surface profile depth required for many industrial coatings.

In choosing traditional abrasives, coatings can either be removed, or the surface can be cleaned – not both at the same time.

A more efficient abrasive

GMA Garnet™ Engineered Blends deliver optimised blasting performance in specific applications. Coarse grains cut through coatings fast and create the required profile depth, while fine grains clean the anchor profile and improve blasting efficiency.

GMA Garnet™ delivers fast and effective coating and rust removal at the lowest possible consumption rate, leaving the cleanest surface ready for inspection and coating application.

Why is GMA Garnet™ the preferred sandblasting media?

Achieve safe, effective blasting with minimized consumption and unmatched coating adhesion.

Surface quality

Our garnet creates the required surface profile with minimal embedment or contamination, and produces higher peak density.

High productivity

GMA reduces your costs with significantly higher blast production rates, giving you shorter project time lines.

Reduced consumption

Lower your abrasive consumption by 30-50%, giving you savings in abrasive purchase costs, as well as transport, storage and disposal costs.

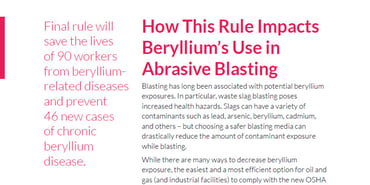

Worker safety

Garnet is a chemically inert mineral, with little to no heavy metals creating worker health and safety risks or environmental contamination.

Low dust blasting

Our garnet fractures less on impact, drastically improving operator visibility and reducing site contamination.

Sustainable resource

Our garnet recovery programs offer a cost-effective and environmentally responsible solution for the disposal of used garnet.

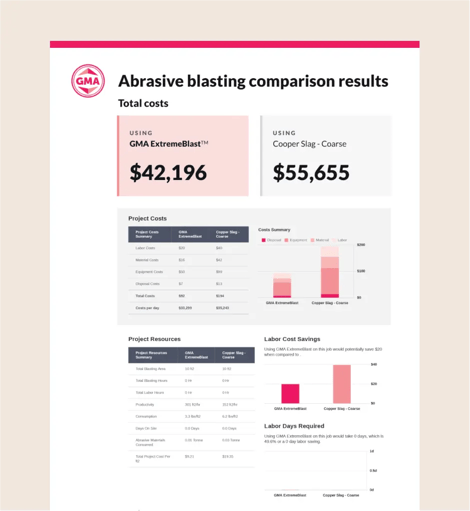

How much can you save with GMA Garnet™?

Your abrasive is costing you more than just it’s price. Find out how GMA can save you money with higher productivity, and lower consumption and disposal costs.

Explore the range

GMA’s range of engineered blend abrasives optimizes your blasting performance in any project.

GMA ExtremeBlast™

The coarsest grade for extreme jobs. Removes high-build coatings of 30+ mils, such as TSA and coal tar.

Surface profile

3.5 - 4.5 mil

Blasting rate

Up to 260 ft2/hr

Consumption rate

As low as 2 lb/ft2

GMA ToughBlast™

Power through thick industrial coatings. An engineered blend for medium to heavy industrial maintenance.

Surface profile

3.0 - 4.0 mil

Blasting rate

Up to 360 ft2/hr

Consumption rate

As low as 1.5 lb/ft2

GMA SpeedBlast™

Fast blasting performance for removing light to medium coatings and rust, producing exceptional surface quality.

Surface profile

2.0 - 3.0 mil

Blasting rate

Up to 360 ft2/hr

Consumption rate

As low as 1.5 lb/ft2

GMA NewSteel™

The fastest mill scale and light rust removal abrasive that minimizes consumption and keeps costs down.

Surface profile

1.5 - 2.5 mil

Blasting rate

Up to 400 ft2/hr

Consumption rate

As low as 1.3 lb/ft2

GMA PrecisionBlast™

Ideal for fast, gentle cleaning of precision equipment, removing mill scale, and preparing various metals.

Surface profile

1.0 - 2.0 mil

Blasting rate

Up to 300 ft2/hr

Consumption rate

As low as 1 lb/ft2

GMA SoftBlast™

The gentlest garnet abrasive for delicate cleaning and restoration, graffiti removal, polishing, and lapidary.

Surface profile

0.5 - 1.0 mil

Blasting rate

Up to 300 ft2/hr

Consumption rate

As low as 0.75 lb/ft2

Sandblasting media resources

Find out how to optimize your next project

Speak to your regional GMA expert to request a sample or demo, or make a product inquiry.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA NewSteel™

GMA NewSteel™ Oil & Gas

Oil & Gas Industrial Fabrication & Maintenance

Industrial Fabrication & Maintenance Marine & Ship Building

Marine & Ship Building TruCost Blast Calculator

TruCost Blast Calculator Product Selector

Product Selector Brochure | GMA Garnet Blast Abrasives

Brochure | GMA Garnet Blast Abrasives News: GMA's Roadmap to Sustainability

News: GMA's Roadmap to Sustainability GMA ExcelCut

GMA ExcelCut GMA ProCut™

GMA ProCut™ GMA ClassicCut™

GMA ClassicCut™ Metal fabrication

Metal fabrication Glass cutting

Glass cutting Stone cutting

Stone cutting Case Study | GMA ClassicCut | Smith and Nephew

Case Study | GMA ClassicCut | Smith and Nephew Why is Garnet the preferred abrasive in Waterjet cutting?

Why is Garnet the preferred abrasive in Waterjet cutting? Water Filtration

Water Filtration Rubber Fillers

Rubber Fillers Anti-skid Products

Anti-skid Products Ilmenite Sand

Ilmenite Sand Pyroxene

Pyroxene Rutile

Rutile