Heavy-Duty Equipment

GMA provides a range of high-performance garnet blasting abrasives for the heavy-duty equipment manufacturing and maintenance industries, helping provide the best surface to protect manufacturers brands and machinery in the harsh environments industrial equipment operates in.

Get a cleaner surface faster, with minimized OSH risks

GMA Garnet™ is approved by leading paint and coating manufacturers around the world. We work extensively with industrial heavy-duty equipment OEMs and has an in-depth knowledge of manufacturer and end user requirements.

High productivity

Achieve your specified surface profile faster than alternate abrasives.

Low consumption

Complete the job with far less abrasive, reducing costs in abrasive purchase, transport, and disposal.

High peak density

Generate higher peak density over alternate abrasives for unmatched coating adhesion and integrity.

Low embedment

60% of the average slag-blasted surface is embedded with residual abrasive. Garnet results in minimal embedment.

Low dust

GMA Garnet™ offers the closest thing to dustless blasting, drastically improving operator visibility and reducing site contamination.

Low safety risk

Garnet is an inert mineral with little to no heavy metals creating worker risks or environmental hazards.

Mining and Construction Equipment

GMA Garnet™ produces the optimal clean and consistent surface profile to maintain, protect and extend equipment uptime and life cycle in the heavy-duty segment. Harsh operating environments need the best surfaces to protect assets vital to running your operation efficiently.

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- Creates the required surface profile with consistent peak density for stronger coating adhesion

- High blasting and cleaning efficiency, leading to reduced asset downtime during maintenance

- Very low dust emissions, reducing risks and hazards to workers

- Inert, sustainable natural mineral with little to no recordable heavy metals and worker hazard risks.

Agriculture

GMA Garnet™ helps extend the life of agricultural equipment such as harvesters, seeders and tractors season after season, thanks to GMA’s optimal surface preparation. Prolonged UV and chemical exposure accelerates aging, and wear and tear. Prolonging coating integrity and reducing asset downtime for maintenance requires the cleanest surface and a consistent profile which GMA Garnet™ provides.

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- Creating the required surface profile with consistent peak density for stronger coating adhesion

- High blasting and cleaning efficiency, leading to reduced asset downtime during maintenance

- Very low dust emissions, reducing risks and hazards to workers

- GMA Garnet™ is an inert, sustainable natural mineral with little to no recordable heavy metals and worker hazard risks.

Rail cars

- Exceptional surface cleanliness with minimal abrasive embedment for better corrosion resistance and substrate integrity

- Creating the required surface profile with consistent peak density for stronger coating adhesion

- High blasting and cleaning efficiency, leading to reduced asset downtime during maintenance

- Very low dust emissions, reducing risks and hazards to workers

- GMA Garnet™ is an inert, sustainable natural mineral with little to no recordable heavy metals and worker hazard risks.

Related content

Safely create clean, consistent surfaces

Find out how GMA can produce the range of surface profiles that your protective coatings require — safely, efficiently, and without disrupting your facility.

GMA PremiumBlast™

GMA PremiumBlast™ GMA SpeedBlast™

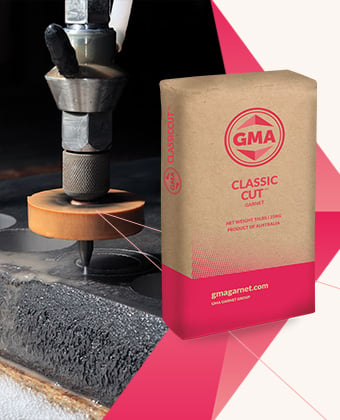

GMA SpeedBlast™ GMA ClassicCut™ 80

GMA ClassicCut™ 80 GMA ClassicCut™ 120

GMA ClassicCut™ 120 Ilmenite

Ilmenite Pyroxene

Pyroxene