You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Product Range

Tools & Resources

Featured products

Tools & Resources

Featured products

Tools & Resources

Resources

Categories

Types

Categories

Topics

Abrasive Blasting Our Customers

Heinrich Schmid replaces slag with GMA PremiumBlast for Salier Bridge corrosion protection project

For cleaner and more efficient abrasive blasting results.

When corrosion protection experts Heinrich Schmid took on the maintenance work for Salier Bridge in Speyer, Germany in 2019, they found the slag abrasives they were using to be underperforming.

Moreover, the dust levels during blasting were very high. The search for a cleaner and higher performing abrasives has led them to GMA PremiumBlast™ garnet.

The Salier Bridge, built in 1956 has two road traffic lanes, pedestrian and bicycle lanes. The 595m (1952ft) long steel bridge spans across the Rhine river between Baden-Württemberg and Rhineland-Palatinate.

According to Henrich Schmid, the old paint coating (thickness between 300 - 450 µm) on the steel beams under the bridge must be thoroughly and safely removed as it contained lead, a dangerous and toxic metal. The workers were required to wear personal protective equipment and enter the worksite via hermetically insulated airlock doors.

The project covered four construction areas of similar size with 1,400m² (15,069ft²) per area and a total area of 5,600m² (60,278 ft²). The blasting works were conducted in two stages due to the presence of hazardous materials. The coating was first removed followed by rust removal in stage two. Therefore, the blasting works in each area were performed twice.

Initially, the first area was blasted with Asilikos coal slag 0.5 - 2.0 mm. The performance was unsatisfactory with high abrasive consumption of 42.86 kg/ m². Moreover, the dust levels were very high, which was a health concern for workers and the environment. It took more effort and a longer time to clean up with reduced safety on site.

GMA PremiumBlast™ was then tested on area two and was found to be more efficient. Not only was the performance increased, but abrasive consumption was also drastically reduced to only 16.07kg/m² (3.3lb/ft2).

In addition, GMA provided a package offer of PremiumBlast™ abrasive and a mobile GMA Blast Abrasive Silo. Filling the blast pots via the silo takes just a few seconds. It also minimizes handling and reduces packaging waste.

In summary, Heinrich Schmid saved 63% in abrasive consumption and the same constructed second area was completed in half the time. Productivity was increased by 100% due to higher blasting speed, reduced cleanup, postprocessing and material handling.

Filling the blast pots via the GMA Blast Abrasive silo takes just a few seconds. It also minimizes handling and reduces packaging waste.

The bridge maintenance project commenced in November 2019 and is expected to be completed in 2021.

Heinrich Schmid GmbH & Co. KG is one of the largest construction companies in the industry with more than 5,200 employees and 170 locations in Europe. Besides painting, fire and building protection and insulation, the company offers corrosion protection services for steel and concrete.

By Christian Arlt, GMA Europe

By Christian Arlt, GMA Europe

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

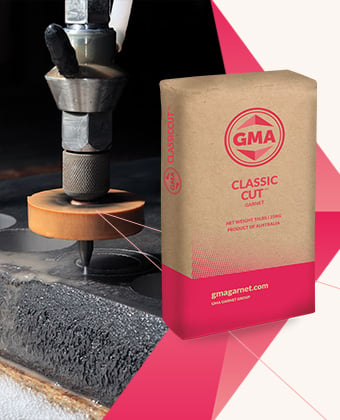

GMA SpeedBlast™ GMA ClassicCut™

GMA ClassicCut™ GMA ExcelCut™

GMA ExcelCut™ Ilmenite

Ilmenite Pyroxene

Pyroxene