You’re currently viewing the Americas website.

You’re currently viewing the Americas website.

Would you like to switch countries or language?Product Range

Tools & Resources

Featured products

Tools & Resources

Featured products

Tools & Resources

Resources

Categories

Types

Categories

Topics

Waterjet Cutting Tech Tips

JetTalk: Calibrating your waterjet machine to lower garnet consumption

Whenever you upgrade your waterjet machines, running calibration and cutting tests will assist you in obtaining an optimal balance between cutting performance and garnet consumption rate.

The type of garnet abrasive used by your waterjet machine also plays a vital role in achieving operational cost efficiencies, optimal cutting speed and cutting edge quality.

It is important to take note of the specifications provided by your supplier as it gives you an idea, the type of garnet, orifice and focusing tube you should and can use for the new machine. Ultimately, you will not only achieve the optimal garnet consumption rates but also keep wear and tear on your waterjet parts to a minimum.

Run a Cutting Test

Whenever a new garnet grade is fed to your waterjet machine, you should calibrate your machine and run cutting tests. Different types of garnet abrasives and mesh sizes can affect the cutting quality and consumption rate depending on your cutting applications.

There are a lot of ways to run waterjet recalibration cutting tests. The steps or methods are dependent on a number of factors such as the type of waterjet equipment, the number of cutting heads, connecting parts, feeding system, application and pressure from the pressure tank to the mini hopper.

However, the aim of this exercise is to maintain or improve the cutting performance of the new machine while lowering the garnet consumption rate per minute.

The thickness and type of application are the only variables that should affect the waterjet machine’s cutting speed. Therefore, it is crucial that you adjust the waterjet machine’s settings to achieve the optimal balance between performance and garnet consumption.

Using High Quality Garnet Abrasive

It is important that you invest in high quality garnet abrasives. The garnet selection criteria shouldn’t be based on price as cheaper products may contain impurities and inconsistent garnet grains.

These can create potential equipment downtime with a significant impact on the cutting performance.

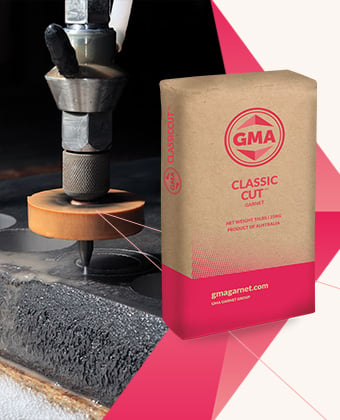

Therefore, always choose consistently sized and high quality garnet abrasives such as GMA Garnet™ for smooth cutting performance and minimal machine downtime.

GMA’s world-class garnet processing technology ensures that every batch of garnet contains highly accurate sized grains of the purest almandine garnet, the hardest and toughest mineral used by waterjet cutting industries.

Moreover, the heavy garnet particles accelerate cutting speed and maximise velocity through the waterjet stream without any blockages. A higher cutting speed gives you greater operational cost efficiency.

In conclusion, selecting the right abrasive and performing machine recalibration and cutting tests not only reduce your operating costs but pro-long the life span of your waterjet equipment.

By Kjeld Lauritzen, GMA Europe

By Kjeld Lauritzen, GMA Europe

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA ClassicCut™

GMA ClassicCut™ GMA ExcelCut™

GMA ExcelCut™ Ilmenite

Ilmenite Pyroxene

Pyroxene