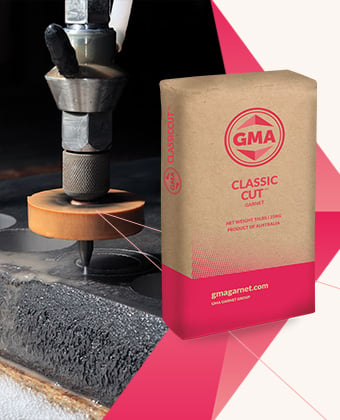

GMA ClassicCut™

The trusted , versatile abrasive choice for precise waterjet cutting.

80 and 120 mesh

Mesh

0.020" - 0.040"

Focusing tube

0.007" - 0.014"

Orifice

GMA ClassicCut™

It is a versatile, all-purpose abrasive ideal for general waterjet cutting and is recognised as the industry standard waterjet cutting abrasive among waterjet manufacturers globally.

Industry Applications

Which mesh size is right for you?

ClassicCut 80: The most popular, general purpose waterjet abrasive, ideal for a wide variety of applications.

ClassicCut 120: High precision and versatile cutting speeds where a narrow kerf is demanded, ideal for thinner, softer, or brittle materials including brass, marble, plastics or ceramics.

| PRODUCT RANGE | FOCUSING TUBE | ORIFICE |

|---|---|---|

| ClassicCut™ 80 | 0.030″–0.040″ | 0.010″–0.014″ |

| ClassicCut™ 120 | 0.020″–0.030″ | 0.007″–0.010″ |

Why choose GMA’s waterjet products?

Secure supply

GMA is the only global garnet supplier to manage their complete supply chain from source and processing to international distribution, giving you minimal disruptions to your consistent supply of garnet.

Consistent quality

Our high standards in processing and quality control ensures each batch contains consistently sized grains of the highest quality almandine garnet. A bag of GMA Garnet™ contains as much as 98% pure garnet. Uncontaminated garnet enables faster cutting and cleaner cuts.

Superior performance

GMA’s waterjet abrasives’ unique grain hardness, density, and toughness ensure the highest production rates and the perfect edge quality with the first cut. Our waterjet garnet can cut virtually any material with a thickness of up to 24 inches.

No oversized grains

GMA Garnet™ has no dust particles or fine grains that hinder garnet flow or oversized grains that block focusing tubes. This means you can count on uninterrupted, efficient cutting from your equipment.

Reduced abrasive consumption

Our unique garnet provides the perfect balance between cutting speed and edge quality, requiring less garnet to make the cut while achieving the best edge quality. This results in direct cost savings and a longer operating life for your waterjet equipment.

Disposal and recycling

GMA has invested heavily in innovative ways to reduce landfill and reprocess garnet, with an expanding number of reprocessing facilities opening around the world.

Related content

Speak to an expert about GMA ClassicCut™

Request a product sample or onsite demo, or find your nearest GMA distributor.

GMA Newsletter

Subscribe to our e-newsletter for the latest news and events at GMA.

GMA ToughBlast™

GMA ToughBlast™ GMA SpeedBlast™

GMA SpeedBlast™ GMA ClassicCut™

GMA ClassicCut™ GMA ExcelCut™

GMA ExcelCut™ Ilmenite

Ilmenite Pyroxene

Pyroxene